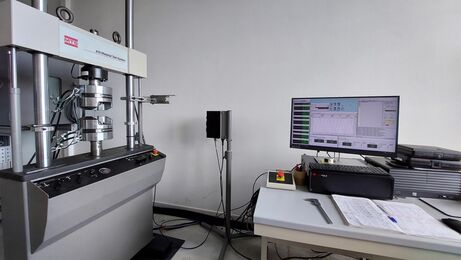

Universal testing Machine for Mechanical tests

The MTS is a universal uniaxial servo-hydraulic mechanical testing machine. It consists, as a base, of a frame (capacity 100 kN), a hydraulic pump and a control unit. The frame features a hydraulic piston controlled by a two-way servo-valve and the entire system for gripping (grasping) the samples to be tested. In addition, a series of sensors are mounted on the frame to measure applied loads (load cell), deformations (extensometers) and displacements of the hydraulic piston (LVDT sensor). With the instrument it is therefore possible to carry out mechanical tests on samples of different types by checking one of the previously mentioned sensors (load, deformation or displacement). The frame is also equipped with accessories that allow hot tests to be carried out using a 3-zone furnace (max 1000°C) and a climatic chamber for tests in a cryogenic environment (down to -100°C in an environment saturated with liquid nitrogen). The instrument is equipped with hydraulic conical gripping systems, both for hot and room temperature tests, and with grippers for flexural tests. In addition, the laboratory also has grasping systems for fracture mechanics tests on CT specimens. As far as extensometers are concerned, the laboratory has linear devices for room temperature and high temperature testing at different L0s (25mm and 10mm). There is also a goniometric extensometer useful for fracture mechanics tests. The system is equipped with a one-channel data acquisition system using MTS software.

The tests that can be performed with this instrument are:

- Tensile tests at room temperature and hot, on both circular and rectangular cross-section samples;

- Uniaxial fatigue tests under load/deformation/displacement control at room temperature and hot temperature, on both circular and rectangular cross-section samples;

- Both static and dynamic 3-point and 4-point bending tests;

- Both static and dynamic fracture mechanics tests at varying temperatures (-100°/+350°C);

Tribometer

The tribometer is an instrument that is mainly used to carry out wear tests in a BOF (Ball On Flat) or POD (Pin On Disck) configuration. The operating principle consists of a counter material , in the form of a ball or pin, being pressed against the surface of the material to be tested, which in turn is set in motion with rotary or reciprocating motion. The instrument is equipped with a two-axis load cell, for measuring both applied and resisting load, and two drivers, one rotational and one alternating motion, in which the samples (discs or parallelepipeds) are housed. In both configurations, it is possible to perform tests in dry or lubricated condition and at ambient or high temperature (up to 700°C). The system is equipped with software for data acquisition and processing. Scratch tests with HRC identifier (scratch tests) can be performed with this instrument, for measuring the adhesion of thin coatings. The instrument was also used to perform tensile tests on threadlike samples and for hardness measurements (HV, HB, HR). The load cells available are max 1 kN and max 10 N. For alternating motion, the test stroke can be adjusted from a minimum of 0.2 mm to a maximum of 20 mm. Counter materials can be manufactured or purchased in any material (metal, polymer, ceramic).

The tests that can be performed are as follows:

- Wear test in dry or lubricated condition at room temperature or high temperature (up to 700°C) in POF and BOD configuration, with friction coefficient detection during the test;

- Scratch test with HRC identifier under constant or variable load;

- HV, HR or HB hardness measurements.

Salt spray chamber/ weathering chamber/Sun box cabinet

These are accelerated tests that are used to assess resistance to corrosion (coated and uncoated metallic materials), to climatic variations (ceramics and polymers) and to ageing agents (polymeric materials, metals with organic coatings.).

Salt spray consists of a chamber in which corrosive fluid (water with controlled salinity or acidic fluids) is sprayed onto the samples usually arranged on a rack. The assessment of degradation is usually done at well-defined periods of time.

The environmental chamber, on the other hand, is a container in which the temperature (-40°C/+160°C) and humidity (0-95% RH) of the chamber are varied with ample control. In this way, with periodic inspections, the degradation of the tested material can be assessed.

Accelerated ageing (sun box cabinet) is a chamber in which rain (usually deionised water) /sun (UV lamp) cycles are carried out on the samples under investigation. The assessment of degradation is done periodically.