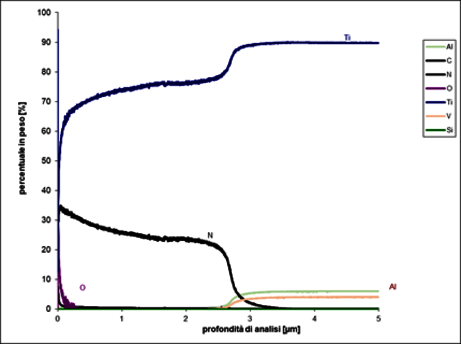

RF-GDOES quantometer

The Rf-GDOES is an optical chemical quantometer/profilometer that works by eroding (solid) material with cold plasma produced in the Glow Discarge regime. The instrument consists of two components: a plasma generator that erodes the material to be analysed and an optical analyser consisting of a polychromator. With this instrument, the material is continuously eroded by the cold plasma, through ionisation, and subsequently stabilised. during stabilisation, a white light is emitted which is then broken down into several light beams of different wavelengths by an optical graticule. the light emitted with different wavelengths is then directed to photomultipliers which are associated with a specific chemical element. The instrument is capable of determining the chemical composition of the material being analysed (28 elements) with an accuracy of approximately 50 ppm. due to the continuous erosion of the material and the simulated analysis of the light beam, the instrument allows the acquisition of chemical profiles with an analysis depth accuracy of 2 nm. With this peculiarity, it is possible to analyse with the instrument, not only the massive chemical composition of the material, but also the elemental distribution over a well-defined investigation thickness. With appropriate calibration, it is possible to obtain quantitative chemical profiles, i.e. as a function of the depth of analysis.

The following analyses can be performed with the following instrument

- bulk analysis of materials (low alloy Fe alloys, Al alloys);

- chemical profilometric analysis on coatings (PVD, ALD, electroplating);

- Chemical profilometric analysis on diffusive profiles (cementation, nitriding, up to a maximum depth of 0.1 mm);

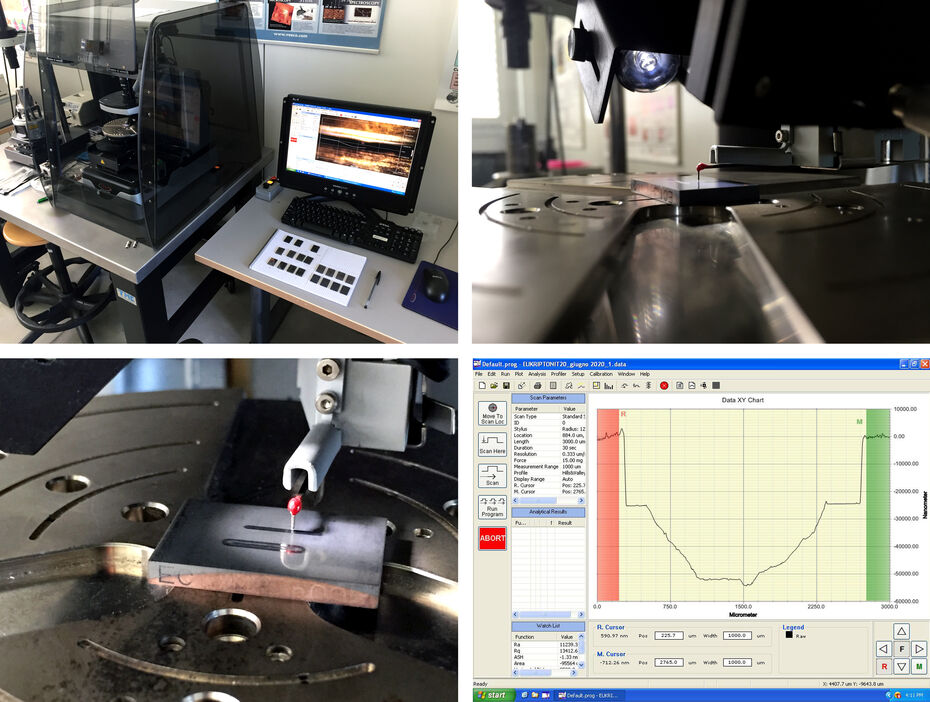

Stylus profilometer

The stylus profilometer is an instrument used for analysing surfaces, especially surface texture. The operating principle is based on a stylus that is brought into contact with the surface to be analysed, which is dragged by moving the stylus along the surface roughness. In this way it is possible to detect, with nanometric sensitivity, the surface profile that can then be analysed in order to tereminister surface roughness (Ra, Rt, Rq, etc.) or surface texture parameters (Sa, St, Sq). In particular, for the last analysis, information is required referring to a large analysis area (map), which can be acquired thanks to the stepping motors with which the instrument is equipped. In this way, it is possible to detect surface morphology by acquiring surface maps. With this instrument, areas of up to 15 cm x 15 cm can be analysed with a maximum height difference of 1 mm and a vertical resolution of a few nanometres. In the case of mapping, the instrument has a lateral resolution of 0.001 mm. The instrument is equipped with software for the analysis of both 1D and 3D acquired profiles.

The analyses that can be performed with this instrument are:

Surface Topography;

Surface roughness and texture measurements;

Analysis of wear profiles;

Atomic Force Microscope

The description of this tool can be found at the following link.